Due to the short tines on this forklift, safety concerns arise, warranting careful consideration. This comprehensive guide delves into the potential hazards, operational guidelines, and workplace modifications necessary to ensure optimal safety when working with short tine forklifts.

As we navigate this topic, we will explore the impact of short tines on forklift operations, discuss load handling considerations, and examine workplace modifications to accommodate these unique forklifts. Additionally, we will emphasize the importance of operator training and awareness, as well as regular equipment maintenance and inspection.

Forklift Time Constraints: Due To The Short Tines On This Forklift

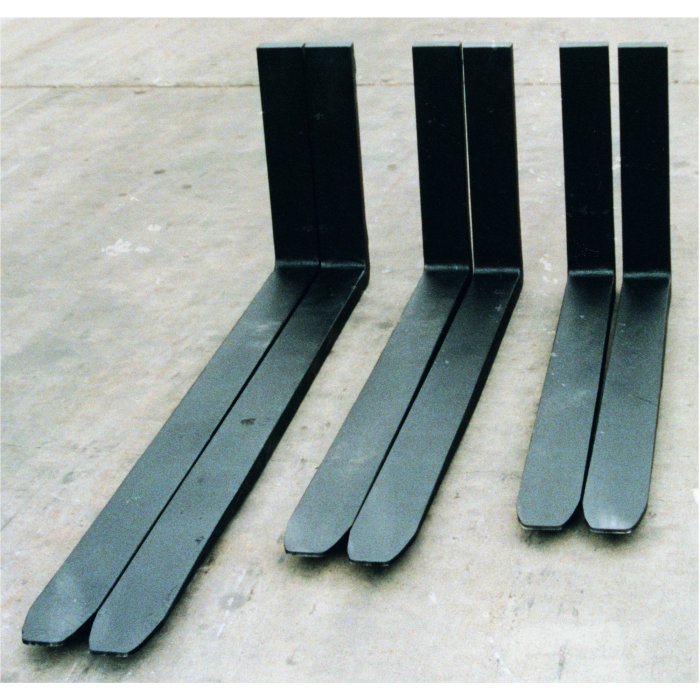

Forklifts with short tines face unique challenges due to the limited length of their tines. This can impact operational efficiency, increase potential hazards, and require specific considerations for load handling, workplace modifications, operator training, and equipment maintenance.

Short tines can limit the forklift’s reach and maneuverability, making it more difficult to pick up and place loads accurately. This can lead to reduced productivity, increased handling time, and potential damage to goods.

Potential Risks and Hazards

- Reduced stability when handling heavy or bulky loads

- Increased risk of load slippage or falling

- Difficulty in accessing narrow or confined spaces

- Potential for collisions with obstacles or other equipment

Load Handling Considerations

To ensure safe and efficient load handling with short tines, operators must follow specific guidelines.

Securing Loads Effectively

- Use appropriate load straps or chains to secure the load firmly

- Position the tines as close to the center of gravity of the load as possible

- Avoid overloading the forklift or exceeding the rated capacity

- Inspect the load and securing devices before lifting to ensure they are in good condition

Workplace Modifications

Workplace modifications can be implemented to accommodate short tines and improve operational efficiency.

Optimizing Storage and Work Areas

- Rearrange storage areas to minimize the need for reaching into narrow or confined spaces

- Use pallet racks with wider aisles to allow for easier maneuverability

- Consider using lifts or ramps to access higher storage areas

- Designate specific loading and unloading zones to reduce congestion

Operator Training and Awareness

Proper training and awareness are crucial for operators using forklifts with short tines.

Best Practices for Operating Forklifts with Short Tines

- Understand the limitations and potential hazards associated with short tines

- Receive specialized training on operating forklifts with short tines

- Follow safe operating procedures and maintain a high level of situational awareness

- Inspect the forklift and tines regularly to ensure they are in good working condition

Equipment Maintenance and Inspection

Regular maintenance and inspections are essential to ensure the safety and reliability of forklifts with short tines.

Regular Maintenance Procedures

- Inspect tines for damage or wear, and replace or repair as needed

- Check hydraulic systems for leaks or other issues

- Lubricate moving parts according to the manufacturer’s recommendations

- Maintain the battery or fuel system to ensure optimal performance

Role of Inspections, Due to the short tines on this forklift

- Identify potential issues early on and prevent costly repairs

- Ensure compliance with safety regulations and industry standards

- Extend the lifespan of the forklift and minimize downtime

Questions and Answers

What are the potential risks associated with short tine forklifts?

Short tine forklifts pose risks such as reduced load stability, increased risk of load slippage, and difficulty maneuvering in tight spaces.

How can I safely handle loads with short tines?

To safely handle loads with short tines, use load stabilizers, ensure proper load distribution, and avoid excessive lifting heights.

What workplace modifications can accommodate short tine forklifts?

Workplace modifications include optimizing storage areas, widening aisles, and installing load stabilizers to enhance safety.